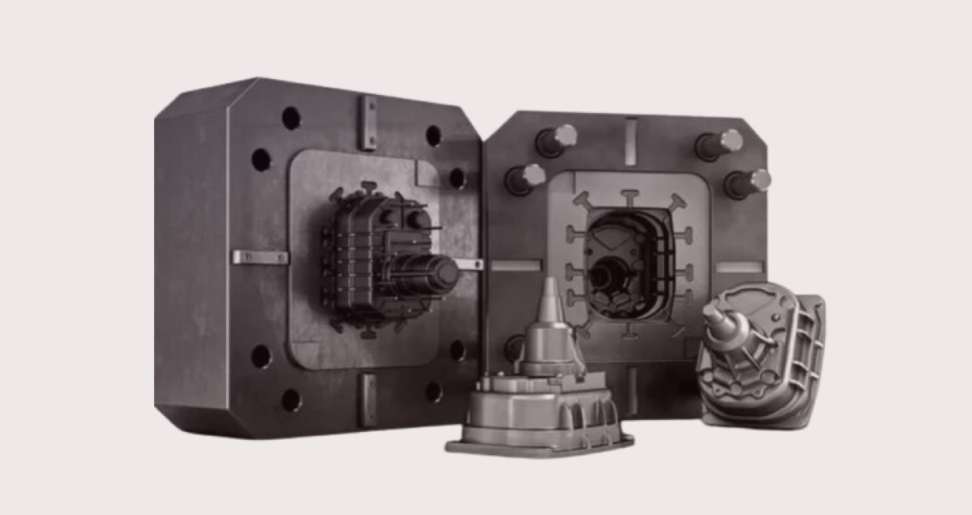

A well-designed die casting mold is crucial for producing high-quality parts efficiently.A well-designed die casting mold is paramount to achieving high production rates, superior part quality, and cost-effectiveness. By carefully considering factors such as part design, mold materials, cooling systems, and manufacturing processes, manufacturers can significantly enhance the efficiency of their die casting operations.

This guide delves into key strategies for optimizing die casting plastic mold design, aiming to maximize productivity while minimizing defects and costs.

Several key factors contribute to mold optimization:

Understanding the Part Design

Design for Manufacturability (DFM): Ensuring the part design is compatible with the die casting process.

Draft Angles: Incorporating draft angles to facilitate part ejection without damage.

Wall Thickness: Maintaining consistent wall thickness for uniform cooling and reduced defects.

Rib and Reinforcement Design: Adding ribs and reinforcements where necessary to enhance part strength and rigidity.

Mold Material Selection

Heat Resistance: Choosing die casting mold materials that can withstand high temperatures and repeated cycles.

Wear Resistance: Selecting materials that resist erosion and wear, extending mold life.

Cost-Effectiveness: Balancing material cost with performance requirements.

Cooling System Design

Efficient Heat Dissipation: Designing an effective cooling system to control solidification rate and prevent defects.

Temperature Control: Maintaining optimal mold temperature for consistent part quality.

Cooling Channel Placement: Strategically locating cooling channels to ensure even cooling.

Gate and Runner System

Optimal Flow: Designing a gate and runner system that ensures complete mold filling and minimizes turbulence.

Gate Location: Selecting the best gate location to avoid hot spots and cold shuts.

Runner and Sprue Design: Optimizing runner and sprue dimensions for efficient metal flow.

Mold Base and Components

Standardization: Using standardized mold base components to reduce design and assembly time.

Modular Design: Incorporating modular components for flexibility and easier maintenance.

Material Selection: Choosing high-quality materials for mold base components to ensure durability.

Simulation and Analysis

Mold Flow Analysis: Using simulation software to predict filling patterns, cooling rates, and potential defects.

Finite Element Analysis (FEA): Analyzing mold stresses and deformations to optimize design.

Design Optimization: Iteratively improving mold design based on simulation results.

Manufacturing and Assembly

Precision Machining: Ensuring accurate and precise machining of mold components.

Assembly Quality: Assembling mold components with tight tolerances to prevent leaks and misalignment.

Surface Finish: Achieving smooth mold surfaces to improve part quality and reduce defects.

By carefully considering these factors and utilizing advanced design and manufacturing techniques, mold designers can create optimized molds that enhance production efficiency, part quality, and overall profitability.

Conclusion

Optimizing die casting mold design is a critical factor in achieving manufacturing excellence. By focusing on factors such as part design, material selection, cooling systems, and manufacturing processes, manufacturers can significantly enhance production efficiency, part quality, and overall profitability.

Continuous improvement and the adoption of advanced technologies, such as simulation and analysis tools, are essential for staying competitive in the evolving die casting industry.

Read Also:

- How Does Upside Make Money?

- Is Other Specialty Stores A Good Career Path?

- How Many Jobs Are Available In Electric Utilities Central?

Feature Image Source: https://tinyurl.com/3jtmxfme